What do you need to pay attention

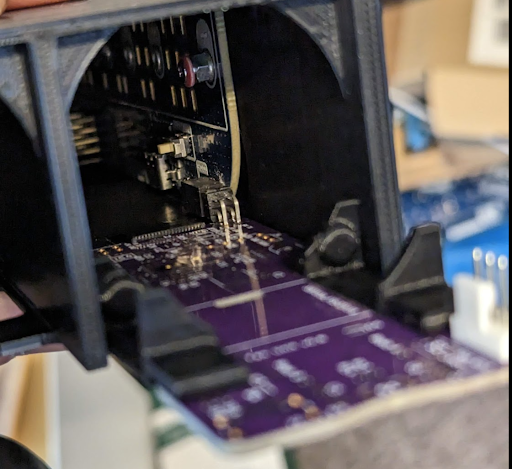

- The current iteration of the 3D-printed enclosure has a weakness. I broke one of the Fan Unit latches by inattention, but in general you just need to not over bend or put the chassis standing on it on the table.

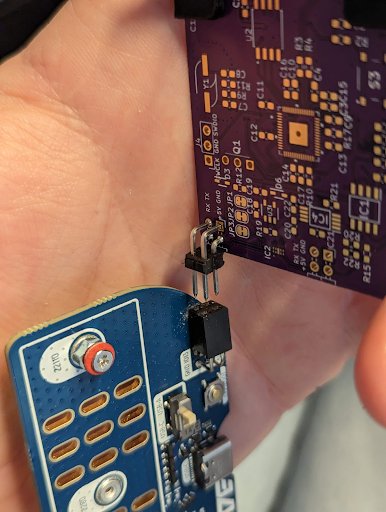

- The second thing to look at is the contact of the Fan Unit assembly.

This may not be the most reliable option, because if the connector or pins are slightly bent, they will not fit together or may break. But this is the cheapest and easiest to replace option. Just make sure the first time that they are flat and fit together. You can start with a fanless assembly to check the case

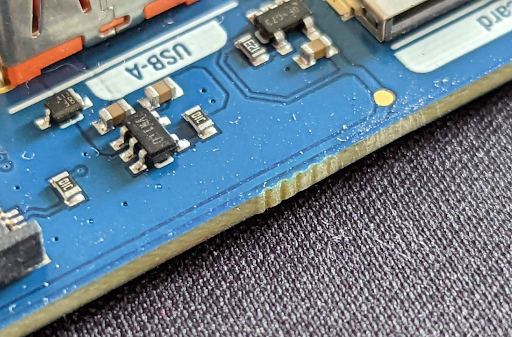

- Processing traces on the edges of the Compute Blade RC2 PCB

Some RC2 blades have irregularities on the borders of the circuit board (the places of separation of the plates), this will be corrected in version 1, but in the meantime need to finalize it with knife or any other tool (incidentally on some blades, I have already done it)

- If you printed the case yourself, note that the blade should go in without difficulty. The model should be printed 1in1 with minimal error. When printing with the Cura slicer, I use a “horizontal expansion” setting of “-0.08” This is the challenge for the 3D printer. Best of luck!